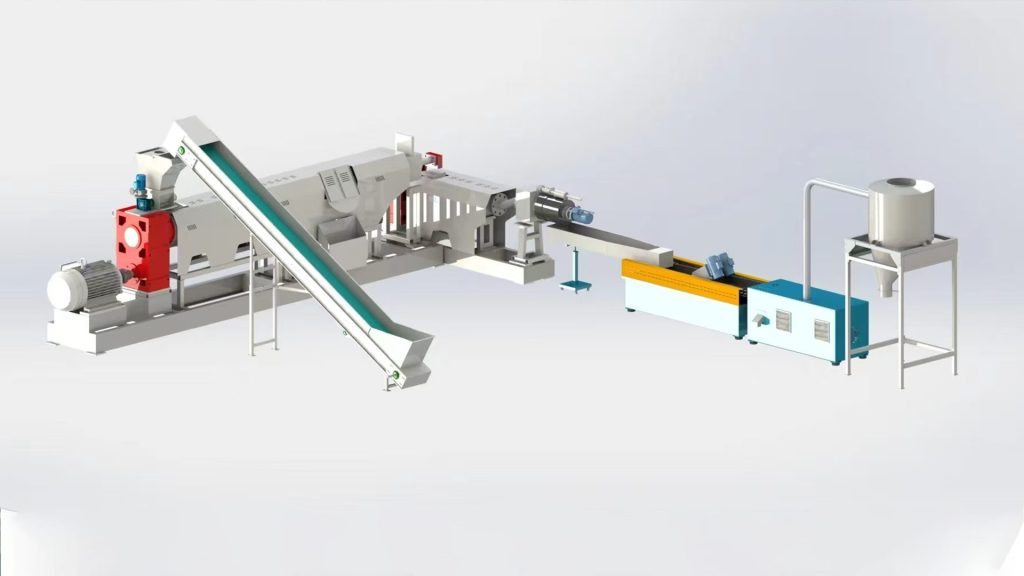

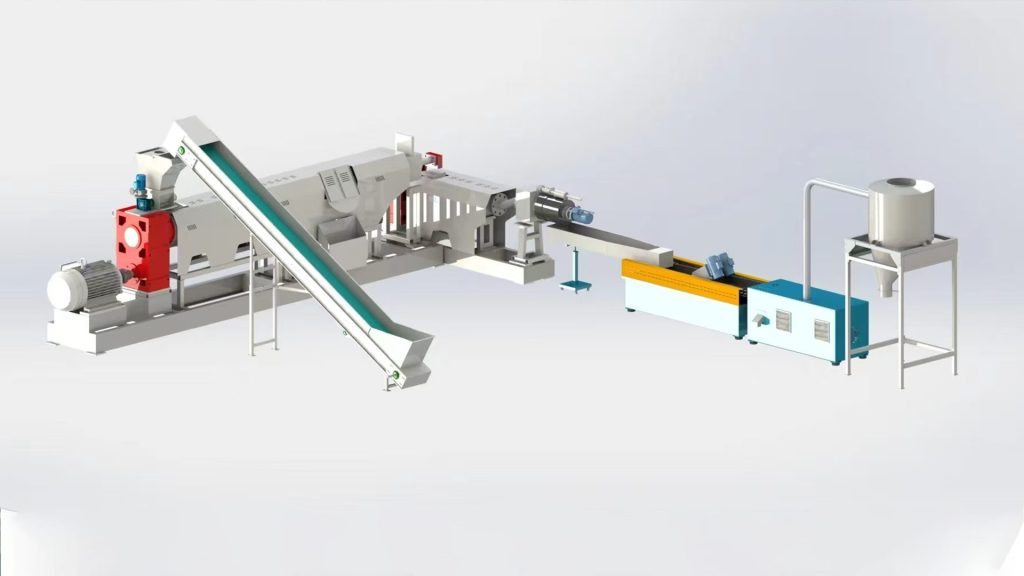

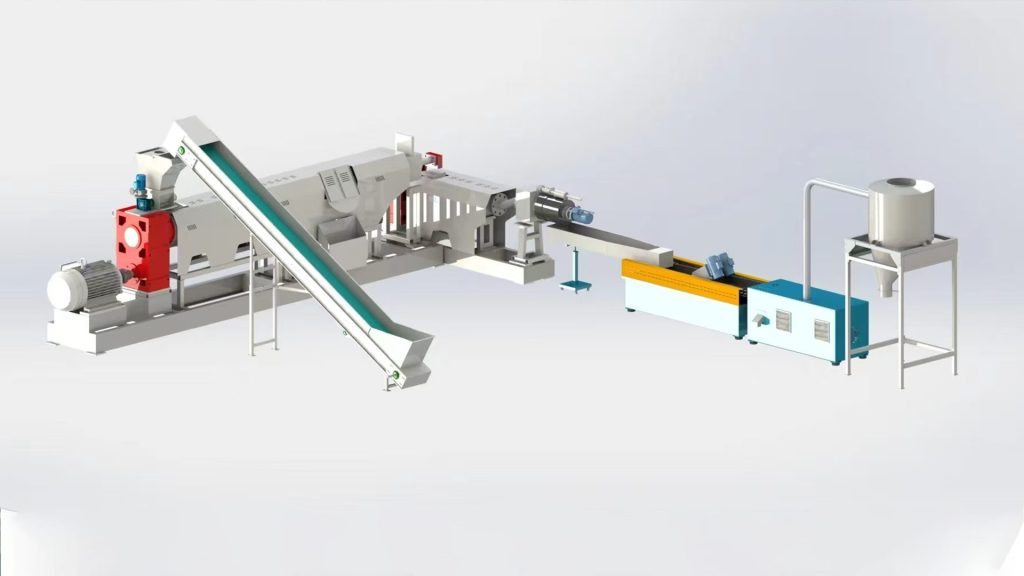

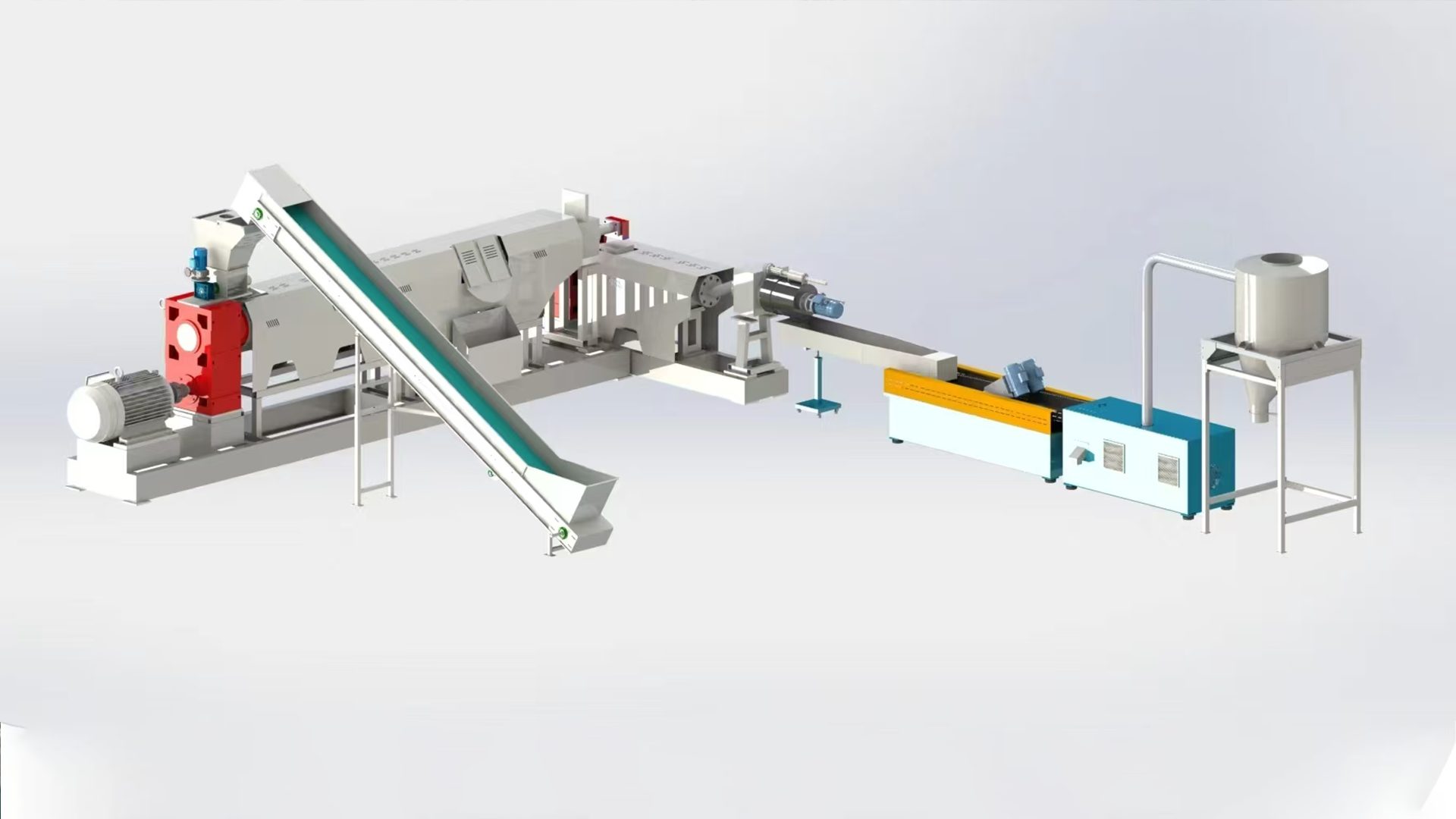

Rigid Plastic Granulating Pelletizing Line

This system processes rigid plastic waste (e.g., HDPE, PP, PS, ABS) into high-quality recycled pellets. Designed for industrial scrap, packaging, and post-consumer rigid plastics, it transforms bulky materials into uniform pellets for reuse in manufacturing.

Product Description

This system processes rigid plastic waste (e.g., HDPE, PP, PS, ABS) into high-quality recycled pellets. Designed for industrial scrap, packaging, and post-consumer rigid plastics, it transforms bulky materials into uniform pellets for reuse in manufacturing.

The pelletizer integrates granulating, extrusion, and cutting technologies to handle tough plastics efficiently. Output pellets are ideal for injection molding, blow molding, or extrusion processes, supporting circular production cycles.

Built for durability, the line emphasizes energy efficiency, low maintenance, and compatibility with mixed rigid plastics. It scales to capacities of 300–3,000 kg/h, serving small recyclers and large-scale facilities.

Process Workflow

Pre-Sorting: Rigid plastics are inspected to remove non-target materials (e.g., rubber, metals).

Coarse Crushing: Shredded into smaller chunks for easier feeding.

Granulating: Reduced to 3–8 mm granules for uniform melting.

Drying (Optional): Moisture-sensitive plastics are pre-dried to <0.5% humidity.

Extrusion: Granules are melted, filtered, and homogenized in the twin-screw extruder.

Pelletizing: Molten plastic is cut into pellets via underwater or strand-cutting systems.

Cooling & Dehydration: Pellets are water-cooled and spun-dried to remove surface moisture.

Screening: Vibrating sieves remove undersized or irregular pellets.

Packaging: Pellets are bagged or stored in silos for industrial reuse.