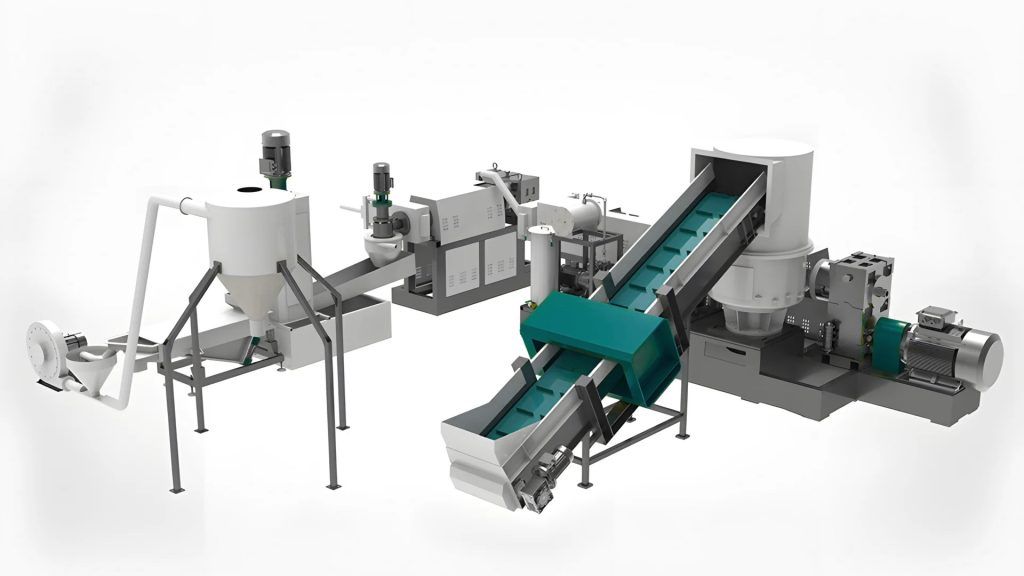

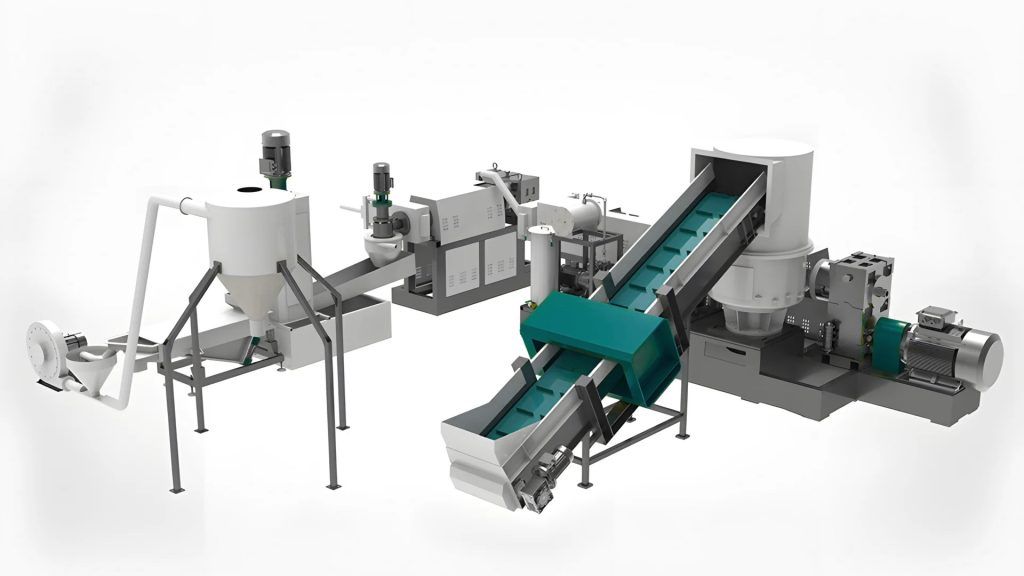

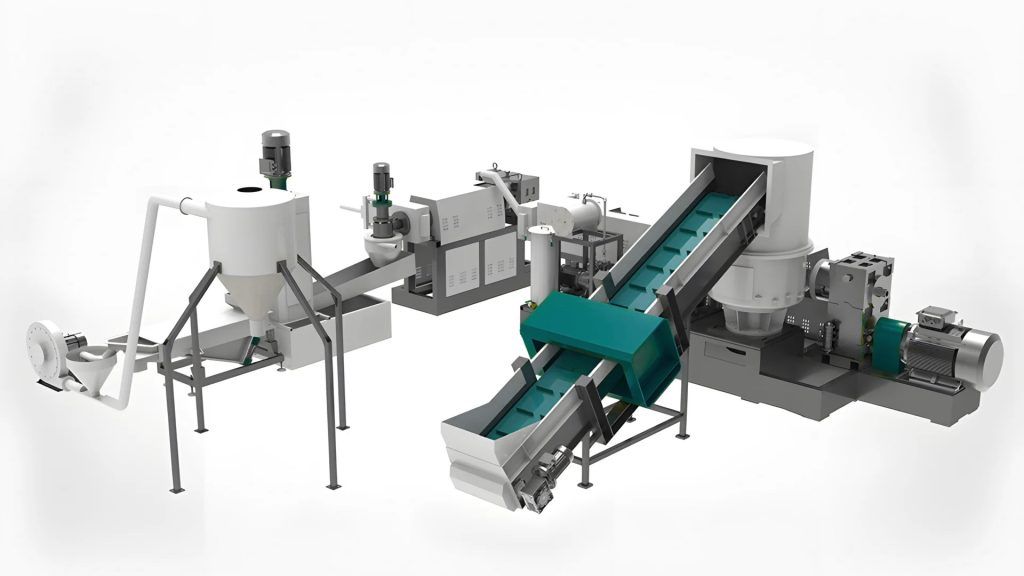

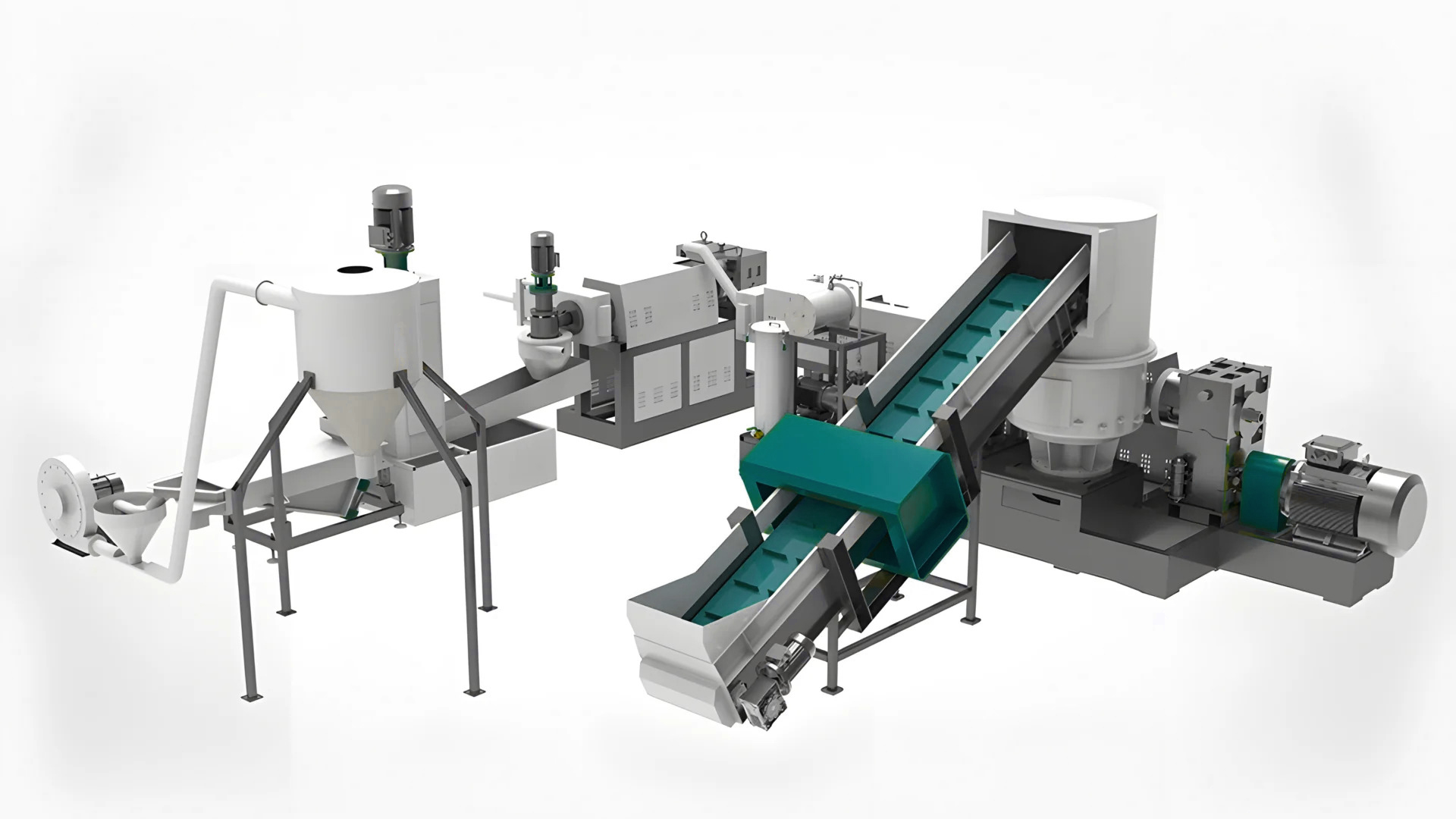

PP PE Film Crushing Pelletizing Line

This line transforms post-industrial or post-consumer polypropylene (PP) and polyethylene (PE) films into high-quality recycled pellets. Designed for plastic films, agricultural mulch, and packaging waste, it removes contaminants like dirt, inks, and adhesives.

Product Description

This line transforms post-industrial or post-consumer polypropylene (PP) and polyethylene (PE) films into high-quality recycled pellets. Designed for plastic films, agricultural mulch, and packaging waste, it removes contaminants like dirt, inks, and adhesives.

The system combines crushing, washing, drying, and pelletizing stages to produce uniform pellets. These pellets are ideal for manufacturing new films, containers, or injection-molded products, supporting circular plastic economies.

Built for efficiency, the line emphasizes low energy consumption, minimal water use, and automation. It scales to handle capacities from 200–2,000 kg/h, catering to small recyclers and large facilities alike.

Key Features

High-Speed Crusher: Shreds films into flakes without tangling, even for lightweight materials.

Multi-Stage Washing: Pre-wash, friction wash, and hot wash remove oils, dirt, and surface contaminants.

Dewatering & Drying: Centrifugal spin dryers and thermal systems reduce moisture to <1%.

Pelletizing Extrusion: Twin-screw extruders melt flakes, filter impurities, and cut uniform pellets.

Material Flexibility: Processes both PP and PE films (LDPE, HDPE) with quick adjustments.

Closed-Loop Water System: Recycles water to cut consumption by 60–80%.

Dust Control: Integrated filters and airflow systems ensure clean operations.

Energy Recovery: Heat exchangers reuse thermal energy from drying stages.